|

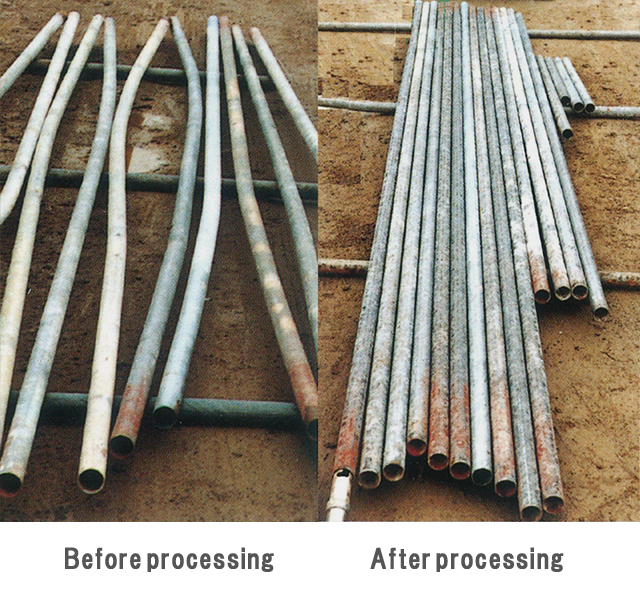

The TP-R’s processing capacity is approximately five times that of conventional pipe cleaning machines (40 m/min.), and it restores straightens pipes at the same time. |

|

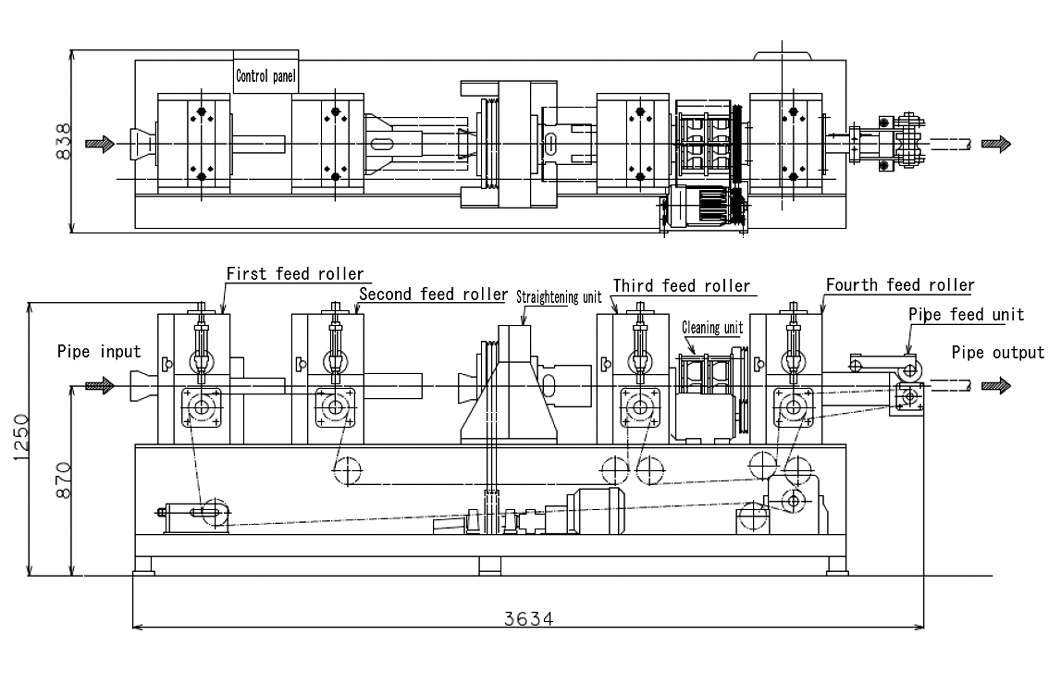

Machine components |

|||

|

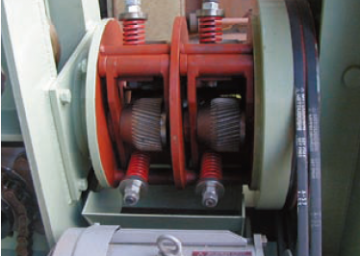

Straightening mechanismThe front and rear rolls are installed to keep reaction force and straightness and make possible the full length of pipes to be straightened by rectification device swings the axis of each pipe with a certain amount of eccentricity applied. |

|

Cleaning rotating drum

The feed roller section crushes concrete deposits, and the deposits are removed when they pass through the center of the rotating drum, which has a crushing roller section and special scraper (a rubber scraper incorporating wire). |

|

Feed rollersFour sets of feed rolls have a function of holding pass line for cleaning and restoring a pipe as well as feeding use. |

|

Control PanelThe operation buttons are easy to use. Also, interlock is available for your safety. |

Straightening methodWhen tensile force is applied to the mild steel, the stress and strain have a proportional relationship. |

Cleaning methodThe feed roll section crushes adhered concrete and the rotary drum with a crushing gear removes the concrete dust by passing the pipe into its center of rotating drum. |

||

Movie |

Specifications |

| Type | TP-R type | |

| Specified pipes | Diameter×thickness | φ48.6×2.4mm |

| Length | Cleaning:1m or more; straightening:2m or more | |

| Motor | For straightening | 2.2kw-200/220V |

| For cleaning | 2.2kw-200/220V | |

| For feeding | 5.5kw-200/220V | |

| Processing speed | Standard:40m/mm | |

| Outer dimensions (L×W×H) (mm) | 3,740×880×1,305(with cover) | |

| Gross weight | 2500kg | |

| Pass line | 870(height of pipe center) | |

| Notes | Includes functionality for converting force to straighten passing rivet-processed products. |

|

| *Specifications are subject to change without notice. *Machine processing capacity figures indicate the capacity of the machine itself. Handling and other process times are not included. |