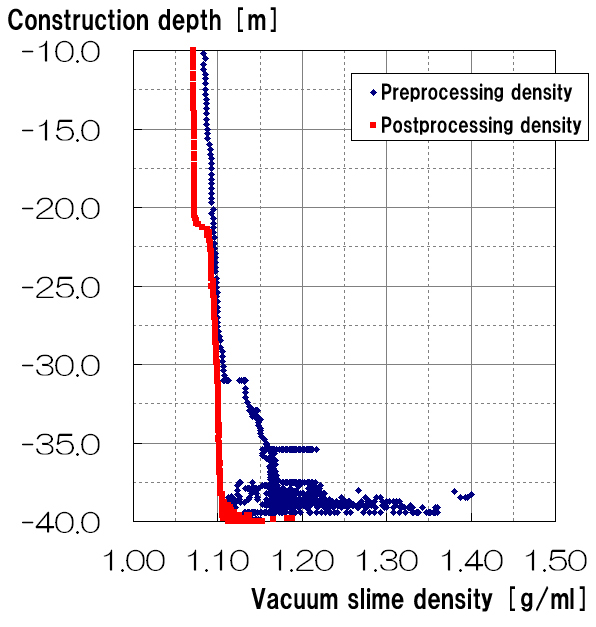

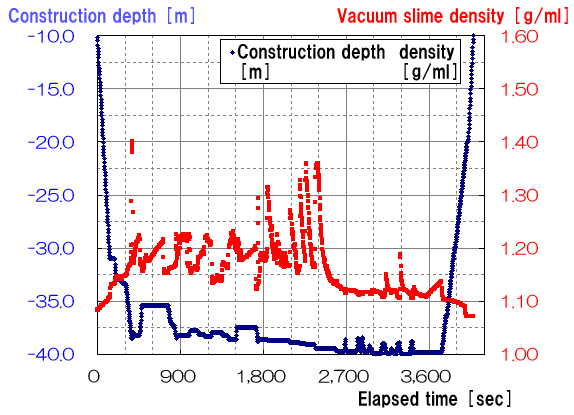

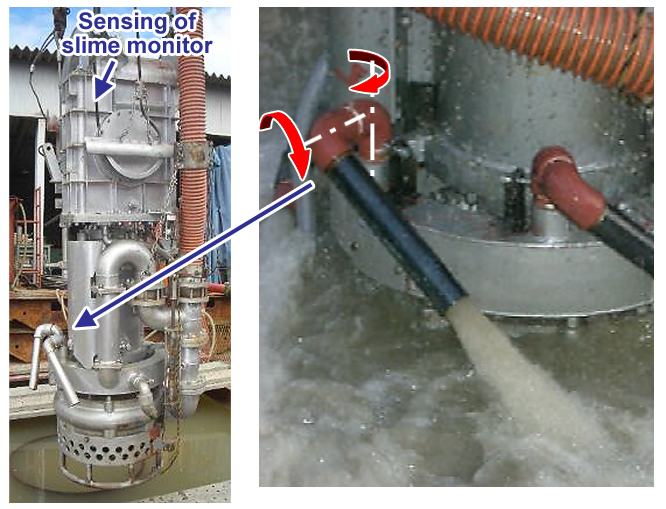

| Visualize the slime processing. Collect the slime at the bottom enlarged position. |

|

|

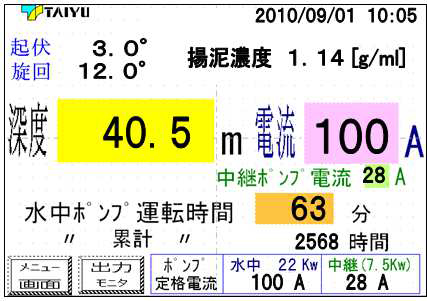

Disrupt and vacuum the enlarged diameter slime using special pump and improve the accuracy of desliming. Real time monitoring of vacuum density makes it possible to shorten the vacuum time by 50% and partially replace high density slurry.

|

|

|

Auto-Slime conceptual movie |

|

|