|

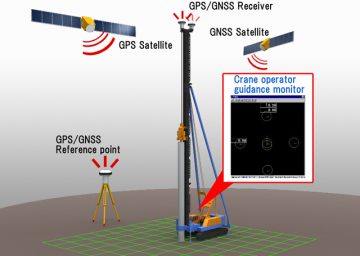

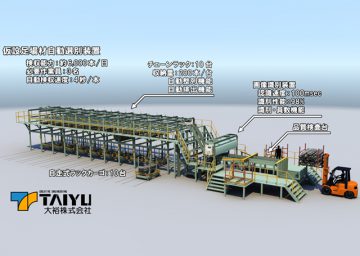

Achieved unmanned construction with low cost and high flexibility.

There has been a increasing demand for unmanned operation comes from frequent and enormous natural disaster and lack of skilled operator of construction machine.

Therefore, TAIYU has developed remote control device with easy retrofit to conventional construction machine.

It makes possible to have unmanned construction operation at lower cost.

●Can be easily retrofitted to the controller without modifying the construction machine.

●No special tools or technique are required to attach the surrogate and can be put on and take off in short time.

●Operator can have boarding operation with device installed.

Co-development with Obayashi Corporation

Surrogate

|